The TRP team spent considerable time with pro team mechanics,

collaborated extensively with athletes and even took soil samples from the various routes

back to our test laboratory in Taichung.

The hardest part of the DHR redesign process:

Redesigning the flow of oil in the caliper was the most challenging and required the most effort and the most time. After we had implemented all of our ideas in prototype solutions, we tested them in the laboratory and with our athletes. The team mechanics gave us a lot of feedback on the vent and we had to pay attention to every detail to come up with the best solution. It felt like sifting little gold nuggets out of a river.

Lessons learned during our extensive development:

We worked with a higher number of prototypes than before and at the same time involved a lot more different testers. In addition to the drivers of our four teams and their mechanics, this was a group of dealers and end users. It was important to us that all testers had different experiences with all products on the market. This heterogeneous mix of international testers was a key factor.

Our a-ha moments:

The change in the development process from product-oriented to customer-oriented and the team mix. Before we started, the team was trained in this agile approach, a challenge for our engineers especially at the beginning. We spent a lot of time with the individual drivers and their mechanics, constantly watching and listening. It always happened in teams, a TRP technician and a marketing or sales person were there. This different way of looking at problems gave us a steep learning curve. Once you got used to it, the work became much faster and more successful.

Performance EVOlution

2.3mm Brake Disc

|

|

New CNC Disc Adapter

|

|

|||

|---|---|---|---|---|---|---|

Ergonomic Brake Levers

|

|

5mm Brake Line

|

|

|||

Performance Mineral Oil

|

|

New Brake Pads

|

|

|||

E-Brake Rated

|

|

9mm Brake Lever Piston

|

|

Experts Agree

Rotor Specifications and Options

Rotor Lockrings

12mm Axle

TRP: TR80 (Alloy) / Tektro: TR50 (Steel)

15-20mm Axle

TRP: TR85 (Alloy) / Tektro: TR55 (Steel)

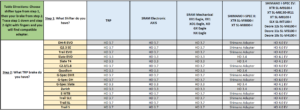

Shifter Adapter Table